-

The South Bend Lathe SB1028F is a powerhouse with a 5 HP motor and variable speeds.

-

Three-axis table movement and built-in power feed on X and Z axes provide precision and ease of use.

-

Constructed with Meehanite® castings for maximum accuracy and longevity.

-

Equipped with a Fagor 3-axis digital readout (DRO) for detailed and accurate measurements.

-

Features such as the Allen-Bradley® controls and Turcite®-B Slydway® enhance the machine’s performance.

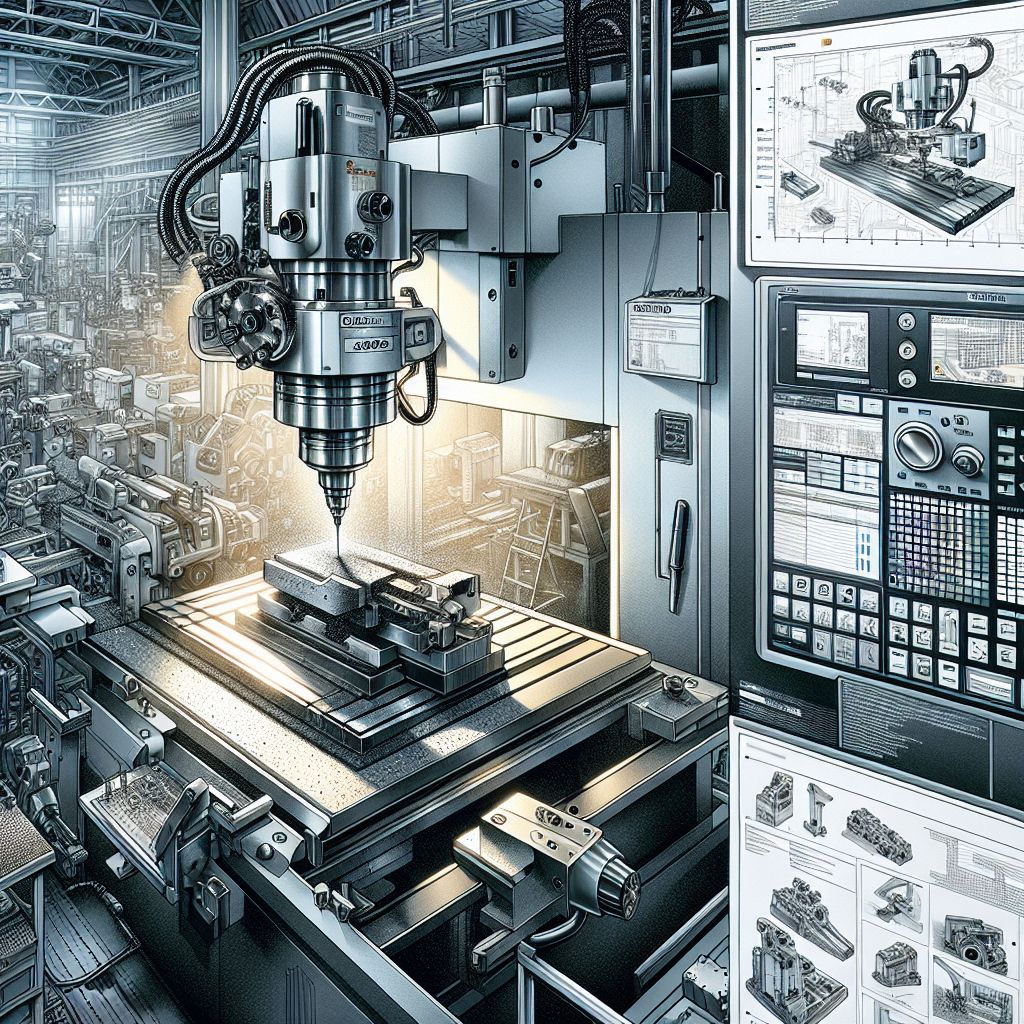

Imagine you’ve just unboxed the South Bend Lathe SB1028F, and you’re about to embark on a journey of precision craftsmanship that’s unmatched. This isn’t just any milling machine; it’s a commitment to excellence, a statement that you’re serious about the quality of your work. Let’s walk through what makes this equipment a must-have for those who don’t compromise on precision.

Unlock Precision Machining with SB1028F

Before we dive into the details, let’s paint a picture. You’re standing in your workshop, and in front of you is the SB1028F. It’s not just a machine; it’s a portal to a world where every cut, every detail, is crafted with the utmost precision. The SB1028F is your trusty companion on this journey.

The SB1028F at a Glance

The SB1028F boasts a robust 5 HP motor, ready to tackle even the most demanding materials. Its large table size, combined with the power of three-phase electricity, ensures that your projects are not only precise but also efficient. It’s a machine built for those who believe that to create something extraordinary, you need tools that are just as remarkable.

Most importantly, the built-in power feed on both the X-axis and Z-axis means that your movements are smooth, consistent, and require less manual effort. It’s about working smarter, not harder, and the SB1028F is designed to be an extension of your own precision-driven mindset.

Making the Most of Your Milling Machine

To truly harness the capabilities of the SB1028F, you need to understand its features and how they translate into real-world applications. Whether you’re creating intricate parts for a custom job or producing high-quality pieces on a larger scale, the SB1028F is up to the task.

Diving Into the Specifications

Let’s get down to brass tacks. The specs of the SB1028F are impressive, but they’re not just numbers on a page—they’re the blueprint for your next masterpiece. The 5 HP motor means you can cut through tougher materials without a second thought. Variable speeds give you the control to adjust based on the task at hand, whether it’s a delicate operation or a full-on assault on a block of metal.

-

Motor: 5 HP

-

Table size: 54″ x 10″

-

Longitudinal travel: 35″

-

Cross travel: 16″

-

Spindle taper: R-8

-

Number of speeds: Variable

Because this isn’t just about power—it’s about the finesse to use that power where it counts. The large table size and travel distances mean that you’re not limited by the size of your projects. You have the freedom to think big, to plan without constraints.

Power and Performance: What the 5 HP Means for You

Imagine the SB1028F’s 5 HP motor as the heart of your workshop, pumping out relentless power and enabling you to push the boundaries of what’s possible. With this kind of horsepower, you’re not just working on projects; you’re dominating them. The variable speeds allow you to adapt to the material’s needs, preserving the integrity of your work and ensuring a flawless finish.

Versatility of Movement: Exploring Axis Feed Capabilities

The SB1028F isn’t just powerful; it’s also precise. The built-in power feed on the X and Z axes transforms your movements into a dance of accuracy. The feed allows for consistent, smooth movements, so you can focus on the intricacies of your craft without worrying about manual adjustments.

Dimensions and Space: Planning for the SB1028F

Now, let’s talk about space. The SB1028F has a footprint that commands respect. It’s not a small machine, and it’s not meant to be. It’s a statement piece in your workshop, a testament to the scale of your ambitions. With a table size of 54″ by 10″, you have ample room to maneuver, to spread out your plans and see them come to life under your hands.

The Digital Readout Difference

There’s a feature on the SB1028F that’s like having a trusted advisor by your side, whispering the exact measurements you need for perfection—the digital readout, or DRO. This isn’t just a fancy add-on; it’s the nerve center of your milling operations, providing real-time data with pinpoint accuracy.

Precision on Display: How DRO Enhances Milling Accuracy

The DRO on the SB1028F is more than just numbers on a screen. It’s a commitment to precision that reads down to a 0.0002″ resolution. Imagine cutting a piece of paper into thousands of slices, then shaving one of those slices even thinner. That’s the level of detail we’re talking about.

“The Fagor 3-axis digital readout on the SB1028F turns complex measurements into a simple, precise science. You’ll know your cuts are accurate to the thousandth of an inch, giving you confidence in every move you make.”

Navigating the Interface: Tips for Maximizing DRO Use

Getting the most out of your DRO means understanding its capabilities. Start by calibrating it for your specific materials and tools. Then, use its readouts to set your zero points with absolute certainty. As you work, trust the DRO to guide your movements—it’s like having a co-pilot for your milling journey. For more detailed guidance, explore our comprehensive article on table saw safety devices, which are integral to precision cutting and measurement.

Remember, the DRO is there to serve you, to make your life easier. Use it to repeat cuts, to ensure consistency across batches, or to dial in complex shapes that would be nearly impossible to eyeball with such accuracy. It’s a tool that elevates your craftsmanship to the level of artistry.

Therefore, take the time to learn its functions. Experiment with different features. The more you understand your DRO, the more it will enhance your work.

Features That Set the SB1028F Apart

But what really sets the SB1028F apart from other mills? Let’s break it down.

The Value of Meehanite Castings

Meehanite® castings are not just any material; they’re the foundation of the SB1028F’s rigidity and durability. Think of Meehanite® as the bedrock beneath a skyscraper—it’s what gives the machine its ability to withstand the stresses of heavy use without flinching.

These castings ensure your mill remains stable during operations, providing the support needed for not just accurate, but consistent results. It’s the difference between a good milling machine and a great one.

Advanced Controls: The Allen-Bradley Advantage

At the helm of the SB1028F’s operations are the Allen-Bradley® controls—renowned for their reliability and precision. These aren’t your run-of-the-mill switches and dials; they’re the result of years of engineering, designed to give you a level of control that’s both intuitive and powerful.

With Allen-Bradley® controls, you’re making adjustments that are as precise as they are effortless. It’s about reducing the margin for error and giving you the power to execute your vision flawlessly.

Why Turcite-B Slydway Matters for Your Projects

Another standout feature is the Turcite®-B Slydway®—a material that lines the ways of the SB1028F, providing a smooth, stick-slip-free motion. This means your table glides under your command, with a resistance that feels just right.

It’s the difference between a choppy sea and a calm lake. Your tools move across the workpiece with a steadiness that can only come from high-quality materials designed for precision work.

Setting Up Your Milling Machine

Now that you’ve seen what the SB1028F can do, let’s talk about getting it up and running. Setting up your milling machine correctly is the first step to ensuring that every project that comes off your table is a masterpiece. For more insights on the best practices in the trade, consider exploring the best construction trades tools and software platforms.

Start by finding the perfect spot in your workshop. You need a space that’s stable, level, and free of vibrations. Once you’ve found it, take the time to anchor your SB1028F securely. This isn’t a job to rush—your future projects depend on this foundation.

Next, go through the calibration process. This is where you make sure every axis is perfectly aligned, every measurement is spot-on. It’s meticulous work, but it’s also what separates the amateurs from the masters.

-

Ensure the machine is level and securely bolted to the floor.

-

Calibrate the DRO for precise measurements.

-

Check the alignment of each axis.

-

Test the power feed for smooth operation.

-

Run a few test cuts on scrap material to familiarize yourself with the controls.

Maintenance is also key. Keep your SB1028F clean, lubricated, and check for wear regularly. A well-maintained machine not only performs better but also lasts longer.

With these steps, your South Bend Lathe SB1028F is not just a machine; it’s a partner in your quest for precision. It’s a statement that you’re serious about your craft, and you have the tools to back it up. Now, let’s get to work and create something extraordinary.

With your SB1028F now firmly a part of your workshop’s arsenal, you’re ready to tackle a diverse array of projects. But to truly maximize the potential of your new machine, regular maintenance is not just recommended; it’s essential.

Consider the SB1028F as a high-performance vehicle. Just as a race car requires regular pit stops for checks and adjustments, your milling machine demands the same attention to detail to maintain its peak performance.

The Importance of Regular Maintenance for Optimal Use

Maintenance goes beyond keeping your machine clean. It encompasses a thorough check of all moving parts, lubrication of the ways, and inspection of the best construction trades tools. It’s the difference between a machine that performs well for a few projects and one that stands the test of time.

Here’s what you need to do:

-

Regularly check and adjust the gibs for minimal play while maintaining smooth movement.

-

Clean the machine after each use to prevent buildup of chips and debris.

-

Lubricate the ways and lead screws as per the manufacturer’s recommendations.

-

Inspect the spindle and collets for wear and replace them if necessary to maintain accuracy.

“Preventative maintenance is the key to longevity and reliability. Treat your SB1028F with care, and it will serve you faithfully for years to come.”

Now, let’s address a common question: Can the SB1028F handle large-scale industrial tasks? Absolutely. The robust construction, precision controls, and powerful motor make it more than capable of taking on large projects. However, remember that with increased scale comes increased responsibility to maintain and check your machine’s tolerances and wear.

Can the SB1028F Handle Large-Scale Industrial Tasks?

Yes, the SB1028F can handle large-scale tasks with ease. Its 5 HP motor and large table size allow you to work on substantial projects that demand precision and power. Whether you’re producing single bespoke pieces or running small production batches, the SB1028F is up to the challenge.

What Materials Can I Work With Using the SB1028F?

The SB1028F is versatile when it comes to materials. Whether you’re working with metals like steel, aluminum, and brass or dealing with plastics and composites, the machine’s variable speeds and power make it adaptable to a wide range of materials.

How Can I Ensure Longevity of My Milling Machine?

Longevity is all about care and respect for your machine. Follow the maintenance schedule, use the correct tooling, and don’t push the machine beyond its limits. Treat it well, and it will be a long-term partner in your machining endeavors.

Are There Upgrade Options Available for the SB1028F?

Indeed, there are upgrade options available. You can enhance your SB1028F with various accessories like additional chucks, clamps, and even more advanced DRO units. Always consider the compatibility and quality of the upgrades to ensure they match the high standards of your South Bend Lathe.

Where Can I Find Technical Support for Troubleshooting?

If you run into any issues or need advice, technical support is available directly from South Bend Lathe’s customer service. They can provide you with expert guidance, whether you’re troubleshooting an issue or looking for tips on optimizing your machine’s performance.

In conclusion, the South Bend Lathe SB1028F is not just a machine; it’s a testament to the craftsmanship and precision that you embody. With its robust construction, advanced features, and precision controls, it stands ready to transform your visions into tangible, high-quality projects. Embrace it as the heart of your workshop, and let it be the catalyst that elevates your work from good to extraordinary.

Option A.