Building processes can be significantly sped up with 3D printing in construction.

Precision printing reduces material waste, which in turn lowers the overall project costs.

3D printing technologies automate many processes, cutting down labor costs.

The technology allows for the creation of complex designs that are structurally sound and visually appealing.

Understanding the potential and limitations of 3D printing is essential for innovators in construction.

Breaking Ground: 3D Printing’s Role in Modern Building

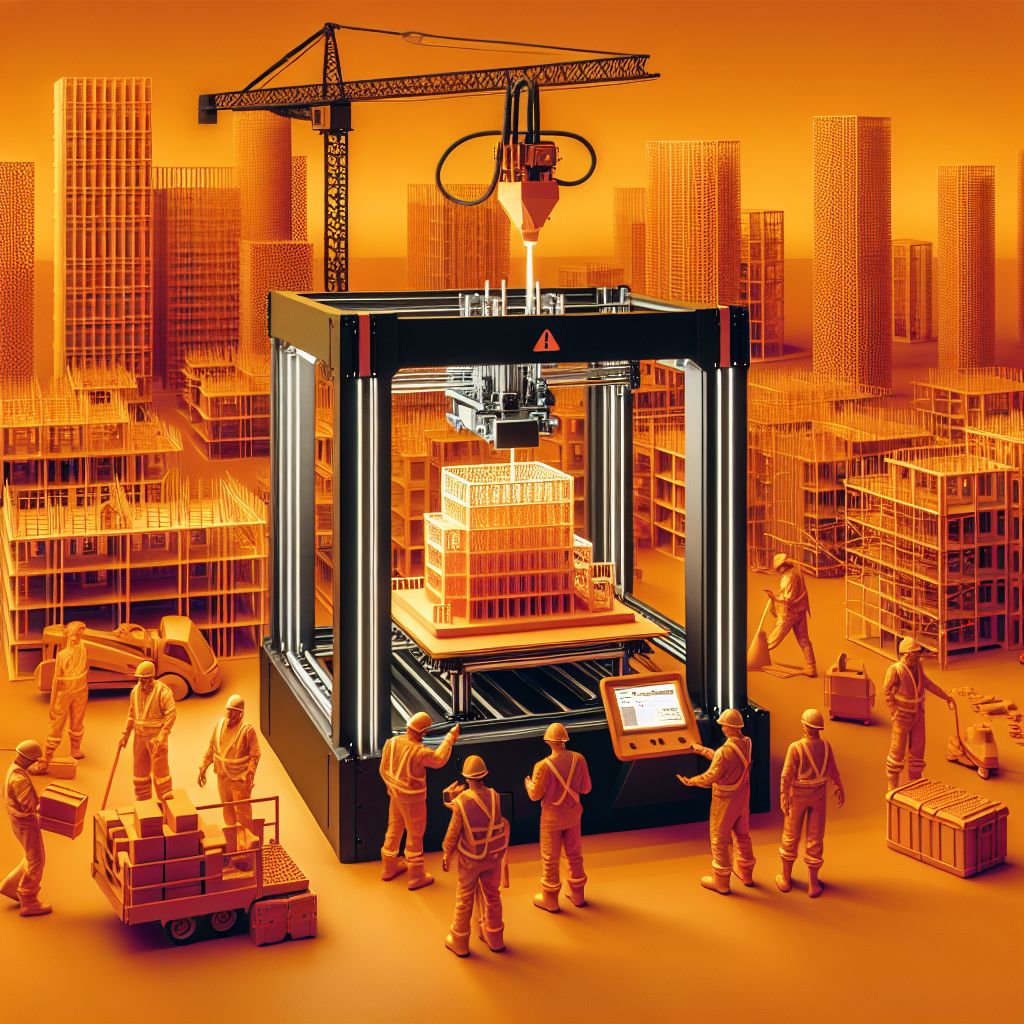

Imagine a world where buildings rise from the ground almost as if by magic, with layers upon layers stacking up to form structures that are both sturdy and intricate. This is not a scene from a science fiction film; it’s the reality we’re moving towards with the introduction of 3D printing in construction. The technology, which has been revolutionizing manufacturing industries, is now set to transform the way we build our homes, offices, and infrastructure.

Understanding 3D Printing in Construction

3D printing in construction, or additive manufacturing, is a process where three-dimensional structures are built layer by layer from a digital blueprint. This is done using specific materials, usually concrete or a composite, which are dispensed by a robotic arm or a printer that moves on multiple axes. This process enables the construction of intricate shapes and forms that would be challenging or even impossible to create using conventional construction techniques.

Contrasting Old School and 3D Print Building Methods

Our minds generally conjure images of laborers setting bricks, spreading cement, and carefully putting together supplies when we think of conventional construction. It’s a method that has stood the test of time, but it’s not without its flaws. 3D printing, in contrast, simplifies the process by automating the construction. Here’s a brief rundown:

|

Conventional Construction |

3D Printed Construction |

|---|---|

|

Materials assembled by hand |

Automated layering of materials |

|

Excessive material waste |

Accurate material usage |

|

Extended construction timelines |

Quick completion |

|

Restricted design complexity |

Complex designs made easy |

From Paper to Reality: How 3D Printing Improves Construction Efficiency

Let’s now delve into how 3D printing is not just a trendy technology, but a game-changer in construction efficiency. We’re talking about real, measurable benefits.

Accelerating Construction Schedules

One of the most notable benefits of 3D printing in construction is the ability for quick building. Given that the process is mostly automated, it can operate 24/7 with little supervision. This implies that what used to take months can now be done in weeks.

Minimizing Material Waste

It’s common to see construction sites with surplus materials that eventually end up in landfills. 3D printing tackles this issue by using only the exact amount of material required for the structure. This is not only cost-effective but also supports sustainable building practices.

Cutting Down on Labor Costs

One of the biggest costs in any construction project is labor. 3D printing reduces the need for a large crew by automating most of the building process. This decrease in labor not only cuts costs but also lessens the chance of human error.

Boosting Building Durability

3D printing also offers the advantage of consistency and accuracy in construction. The automated nature of this process guarantees uniform quality across the structure, which can improve the overall strength and lifespan of the building.

Bricks and Bytes: Groundbreaking Projects in 3D Printing

Let’s discuss some practical examples that demonstrate the potential of 3D printing. These projects are not just concepts; they’re fully operational buildings that validate the feasibility of 3D printing as a construction technique.

Case Study: The World’s First 3D Printed Office Building

In Dubai, the world saw the first-ever 3D printed office building. Completed in just 17 days of printing and at a significantly lower cost than traditional methods, this project is a testament to the efficiency of 3D printing in construction.

Highlighting the potential for social impact, 3D printing in construction is not just about grand buildings; it’s also about addressing critical needs like affordable housing. By significantly lowering the cost and time required to build homes, 3D printing technology is opening doors to housing solutions that were once thought impossible.

Highlight: 3D Printing Providing Low-Cost Housing Solutions

3D printing is being utilized in different corners of the globe to swiftly and efficiently produce low-cost housing. For example, a project in Mexico that sought to fight homelessness used 3D printing to construct houses for families in need. These houses were built in less than a day’s worth of printing time, showing how this technology can offer a lifeline to those who desperately need a place to live.

Furthermore, 3D printing’s flexibility makes it possible to tailor homes to unique environmental and cultural requirements, making it a one-size-fits-all solution to housing issues worldwide.

Future Infrastructure: More than Just Buildings

However, it’s not just buildings that can be 3D printed. This technology has also made significant progress in infrastructure. Bridges, which are complex structures that need careful engineering, can now be printed with accuracy and durability.

Amsterdam is home to a steel bridge that was created using 3D printing technology and placed over one of the city’s historic canals.

In China, a 26.3-meter-long bridge made of concrete was printed in a mere 450 hours, demonstrating the time-saving capabilities of this technology.

These instances illustrate how 3D printing is expanding the limits of what can be achieved in construction, providing new answers to longstanding engineering problems.

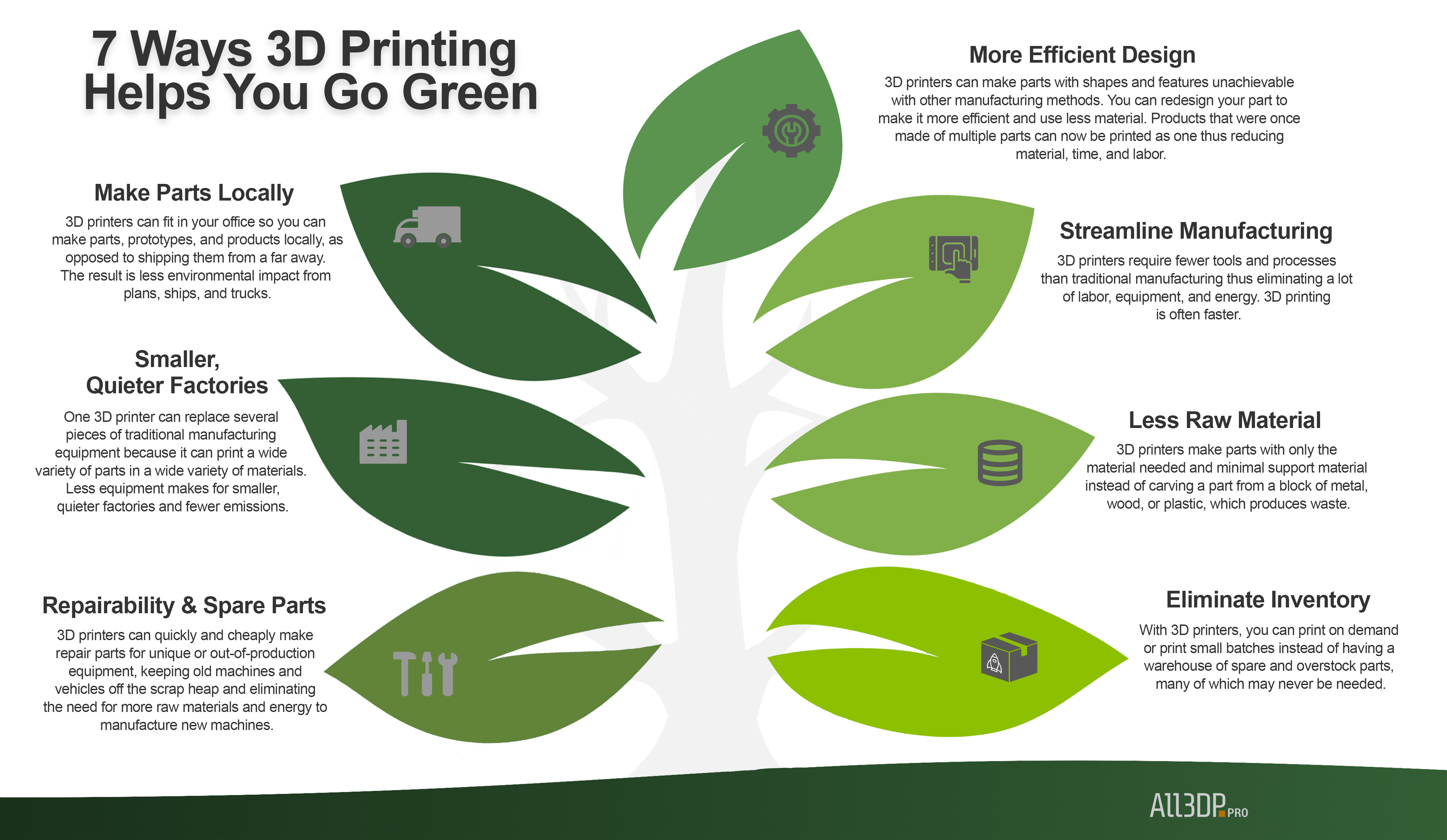

“7 Ways 3D Printing Helps You Become …” from all3dp.com and used with no modifications.

Building Up: The Economic and Environmental Advantage

The economic and environmental benefits of 3D printing in construction are closely linked. The technology not only makes construction more cost-effective but also encourages sustainability.

Investment and Long-Term Savings: A Cost Analysis

3D printing technology can be a considerable initial investment, but the long-term savings are hard to ignore. Here’s a look at the potential costs and savings:

3D printing allows for precise printing, reducing waste and lowering material costs.

The automation of the construction process via 3D printing means fewer labor costs.

Less time spent on construction means lower overhead costs.

As a result, the total cost of a 3D printed building can be significantly lower than that of a building constructed using traditional methods.

Environmentally Friendly Building for a Greener Tomorrow

3D printing isn’t just cost saving; it’s also environmentally friendly. This technology has a smaller carbon footprint than conventional building methods because it uses materials more efficiently and produces less waste. The fact that it can use recycled materials makes it even more appealing from an environmental standpoint.

Picture a construction site that produces almost no waste, creates less noise, and releases fewer emissions. This is the potential of 3D printing, positioning it as a key player in environmentally friendly construction methods.

Building a New World: The Hurdles of 3D Printed Construction

3D printing in construction offers many advantages, but it also comes with its own set of challenges. As we explore this emerging field, it’s important to recognize and confront these issues directly.

Regulation Hurdles and Adherence to Building Codes

Construction is an industry with stringent regulations, and rightfully so. Safety and resilience are of utmost importance. However, building codes have not yet completely adapted to the innovative methods of 3D printing, creating a regulatory grey zone. It’s essential for pioneers to collaborate with lawmakers to create standards that guarantee safety without suppressing innovation.

Technological Boundaries and Dependability of Equipment

Despite 3D printing’s immense promise, the technology is still in its infancy. The reliability of equipment can be questionable, and the selection of materials that can be used is presently restricted. Continued research and development are critical to surmounting these obstacles and unleashing the full power of 3D printing in construction.

Shaping the Future: The Potential Impact of 3D Printing

The future of construction is rapidly evolving right in front of us. As 3D printing technology continues to develop, we can anticipate more creative uses and enhancements in construction methods.

Uncovering the Potential of 3D Printed Construction

Researchers are pushing the boundaries of what can be used in 3D printing for construction, from tried-and-true concrete to innovative composites. As the materials used in 3D printing evolve, so too will the possibilities for 3D printed buildings, potentially reshaping our understanding of design and architecture.

How can you contribute to this revolutionary process? The answer is straightforward: remain inquisitive, continue to educate yourself, and when the chance presents itself, take the plunge and delve into the technology firsthand.

Pushing the Boundaries: Broadening Use Cases

Make a Move: Uncover the Power of 3D Printing

We are on the cusp of a new age in construction, and it is evident that 3D printing is not just a passing fad, but a game-changer. It is high time for construction experts, pioneers, and hobbyists to adopt this technology. The initial step is to experience the features and advantages for yourself.

Get Started Today with a No-Risk Free Trial

There’s never been a better time to explore the benefits of 3D printing in the construction industry. Many businesses offer a free trial period so you can try out their software and printing capabilities before you commit. HighLevel is one such platform. They offer a 14-day free trial, allowing you to dip your toes into the world of 3D printing without any upfront costs. It’s a great way to see if this technology is right for your next project.

Trying out 3D printing in your upcoming project might be the breakthrough you need. By using a free trial, you can play around with designs, learn about the process, and evaluate the advantages without any risk. Who knows? You might just discover that 3D printing is the secret to boosting efficiency and creativity in your construction projects.

How does 3D printing in construction save time compared to traditional methods?

3D printing speeds up the construction process by automating intricate tasks that would normally take more time and manpower. The accuracy of 3D printers ensures that each layer is added swiftly and accurately, eliminating the need for adjustments and reducing the overall time from idea to finished product.

What types of materials are suitable for 3D printing in construction?

The selection of materials for 3D printing in the construction industry is growing. At present, concrete and a variety of composites are regularly used, but studies are being conducted on the use of recycled materials, polymers, and even metals. Each material provides different advantages, ranging from sustainability to structural integrity, paving the way for new opportunities in construction.

Is it possible to construct big structures such as houses and bridges with 3D printing?

Indeed, it is possible to construct big structures using 3D printing. Houses, office buildings, and even bridges have been successfully built using this technology. The secret is in the scalability of 3D printers and the capability to print sections of larger structures that are then put together on-site.

What could go wrong with 3D printing in construction?

Regulatory uncertainty: 3D printing is still a novelty in the construction world, so there might not be any solid regulations or building codes.

Technical difficulties: The technology is still a work in progress, and there might be problems with the reliability of the printer or the performance of the materials.

Workforce disruption: Automation could change the demand for labor, requiring new skills and potentially replacing traditional construction jobs.

Despite these potential pitfalls, the potential for 3D printing in construction to increase efficiency, reduce waste, and create innovative structures is huge. By staying informed and prepared, the industry can successfully navigate these challenges.

How can I use 3D printing technology for my construction projects?

To start using 3D printing for your construction projects, follow these steps:

Keep up-to-date on the newest 3D printing technologies and search for providers that offer solutions specifically for construction.

Think about the specific needs of your project, like the types of structures you want to construct and the materials you plan to use.

Use free trials, such as the one offered by HighLevel, to gain practical experience with the software and printing process.

Participate in workshops or webinars on 3D printing in construction to deepen your knowledge and network with other professionals.

Speak with experts who have incorporated 3D printing into their projects to gain insights and best practices.

By taking these proactive measures, you can place yourself at the cutting edge of the construction industry’s future, ready to take advantage of the efficiency and creativity that 3D printing provides.

Keep in mind, the future is for those who are ready to innovate and adapt. 3D printing in construction is not just a technological advancement; it’s a new perspective on how we construct our world. So why hesitate? Begin with a free trial and be part of the revolution in on-site efficiency today!

Leave a Reply